In today’s competitive manufacturing landscape, companies always look for new methods to streamline production and reduce overhead costs. Laser Cutting Services have emerged as a pivotal solution as businesses search for ways to enhance precision and accelerate turnaround times. This advanced technology is transforming how manufacturers approach fabrication, enabling greater accuracy, flexibility, and speed across various industries.

Streamlined Production Processes

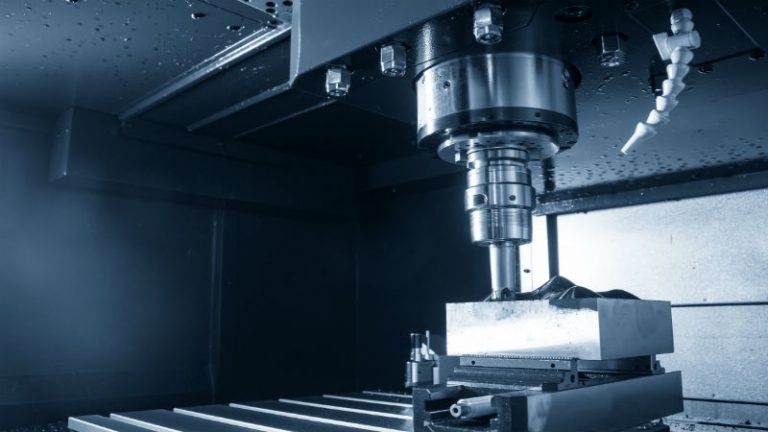

Integrating laser cutting into your production line brings immediate efficiency benefits. Unlike traditional cutting techniques, laser cutting utilizes focused beams to make highly accurate cuts on metals, plastics, and other materials. This process reduces material waste and the need for secondary finishing, saving time and resources. Additionally, the non-contact nature of laser cutting minimizes tool wear and maintenance, leading to fewer interruptions in production.

Key Advantages of Laser Cutting Integration

Businesses that adopt laser cutting technology can expect several tangible benefits:

- Precision and Consistency: Laser cutting delivers repeatable, high-quality results even on complex geometries, ensuring uniformity across large batches.

- Speed and Flexibility: Automated laser systems can quickly adjust to different designs, allowing fast prototyping and swift changes in production without costly retooling.

- Reduced Labor Costs: Automation reduces the need for manual intervention, lowering labor expenses and minimizing the risk of human error.

- Material Versatility: From thin sheets to thick metal plates, laser cutters easily handle a wide range of materials and thicknesses.

Improved Scalability and Customization

Manufacturers often face challenges when scaling up production or introducing customized parts. Laser cutting addresses these needs by offering rapid setup times and digital control, making it easy to switch between projects or accommodate unique specifications. This flexibility supports just-in-time manufacturing and helps businesses respond quickly to market demands.

Integrating laser cutting into your workflow boosts operational efficiency and positions your business for future growth. For companies seeking to modernize their production capabilities, contacting Staub Manufacturing Solutions is a smart step. Reach out to them today to learn more about High Speed Laser Cutting and how it can drive your business forward.