As American factories continue to evolve alongside rapid technological advancements, the demand for a highly skilled workforce has never been greater. In today’s manufacturing landscape, the ability to adapt and excel in areas such as automation, digital design, and precision engineering is critical. Many industry leaders seek ways to enhance their teams’ capabilities to keep pace with modern trends. Individuals searching for “Fabrication Production” often want insight into how workforce development can drive quality and efficiency in manufacturing. Fabrication Production provides a comprehensive overview of the processes and skills required for those interested in exploring this further.

Blending Traditional Skills with Advanced Technology

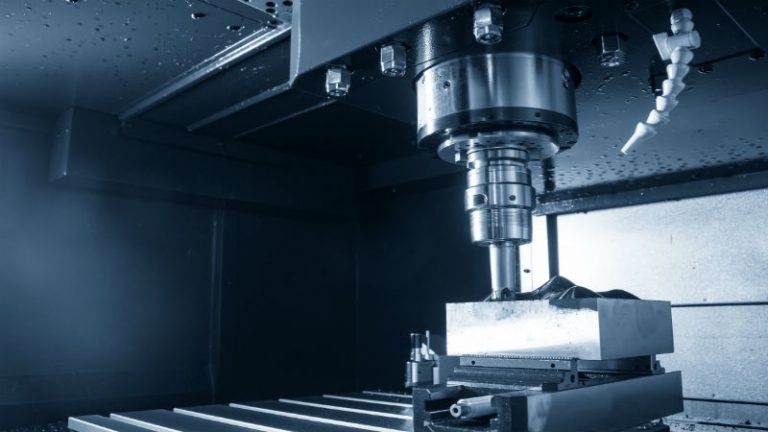

Modern fabrication relies on a blend of traditional craftsmanship and advanced technology. Employees must be proficient in operating CNC machines, interpreting digital blueprints, and adhering to strict safety standards. Emphasizing continuous training helps bridge the gap between legacy techniques and innovations, ensuring that staff remain competent with the latest equipment and protocols. Also, fostering a lifelong learning culture enables workers to adapt to evolving industry requirements and minimizes costly errors or rework.

The Role of Soft Skills in Modern Fabrication

Soft skills are equally important in today’s fabrication environment. Effective communication, problem-solving abilities, and teamwork contribute to smoother workflows and enhanced productivity. By encouraging cross-functional collaboration, factories can leverage diverse perspectives to overcome challenges and implement process improvements. Moreover, investing in mentorship programs and on-the-job training accelerates skill acquisition and strengthens employee retention and job satisfaction.

Upskilling for a Digitally-Driven Future

Adopting digital tools and automation in fabrication production further underscores the need for targeted upskilling. Familiarity with computer-aided design (CAD) software, programmable logic controllers (PLCs), and data analytics is increasingly essential for optimizing production lines. Factories prioritizing digital literacy and technical training are better positioned to maintain high standards, meet tight deadlines, and respond swiftly to market demands.

American factories must prioritize workforce development at every level to remain competitive in the modern manufacturing arena. Contact Staub Manufacturing Solutions today to learn more about their expertise and how they can assist you as a trusted Sheet Metal Fabrication Supplier for your production needs.