Aluminum, in its many guises is a popular metal that is used to produce many lightweight, durable and corrosion resistant products. An aluminum fabricator is the person who takes the material, cuts it, bends it and welds it to produce the desired finished product. An aluminum fabricator must have a number of skills which include certain knowledge of metallurgy, welding, polishing, etc.

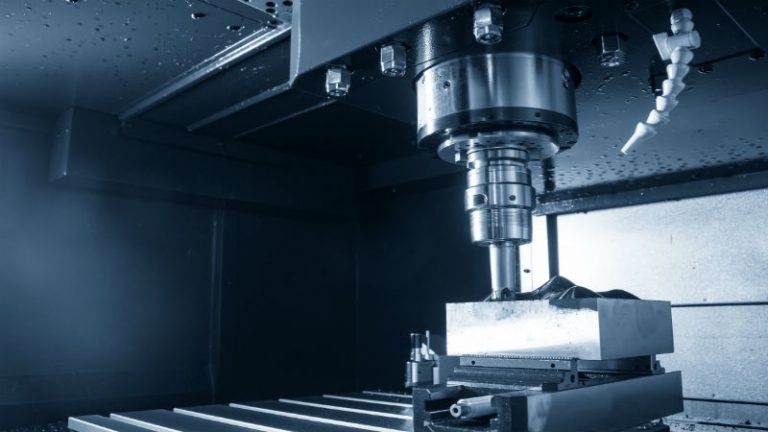

A fabricated part starts with various types of aluminum; the shapes can be flat sheet, aluminum angles or other extruded shapes as well as square or round billet. Two of the core skills of the aluminum fabricator are cutting and bending. Aluminum is not like steel, it cannot tolerate cutting with an open flame torch, an aluminum sheet is cut with a shear and most shapes are cut with saws of different sizes and use. As shears and saws are large, heavy pieces of equipment, cutting and shaping aluminum does not lend itself to be done on site as does steel fabrication, it is done in a factory setting. There is one common exception to this rule and that is the production on-site of roof gutters. In this business, the gutter company has a purpose built vehicle that takes aluminum coil stock, runs it through a series of rollers to produce and assemble the gutters at the site.

Welding is another important skill for any aluminum fabricator to have. Welding is a process which uses heat to join two pieces together, this is done using electricity. The base aluminum angles are heated and aluminum filler in the shape of a wire is melted, fusing the pieces at the joint. The process of welding aluminum puts off a toxic fume; the welder must take particular care and wear breathing apparatus when performing this process.

When the product has been completed it will either be left as is with the natural brushed aluminum finish or polished to a high sheen or gloss. Polishing aluminum is another special skill, the worker, using buffers and various compounds can buff the surface until it is very bright and shiny. The process is completed in stages, starting with rather course buffing compound and working toward using finer compounds until the desired effect has been reached. In many manufacturing facilities, the same worker will produce the product from shapes such as aluminum angles all the way through the finish polishing.

When you need aluminum fabricators who know how to get the job done professionally, you can depend on Vista Manufacturing Company to provide you with the right solutions.