Your home and its interior look a lot different when you stop to think how certain elements in it are produced. How different would it feel if the frame was made of a material other than wood? What if the insulation wasn’t fiberglass? And, what if your eating utensils weren’t made of stainless steel?

The World of Fabrication

Back in the day, silverware wasn’t made of this sturdy metal. However, thanks to steel fabrication methods, you can purchase extra forks and spoons at any time. You can also pick up doorknobs, air conditioners, washing machines, and various fasteners, and it all starts with steel fabricators.

How Does It Work?

In today’s world, a representative metaphor of steel fabricators could be the character Bender from the animated series The robot’s goal was basically to bend metal rods. Fabricators do this and much more.

They bend, cut, twist, and punch holes into metal. And, with the proper templates, the result can be anything from a candle holder to a refrigerator, or, as was mentioned above, eating utensils.

What Methods Are Used?

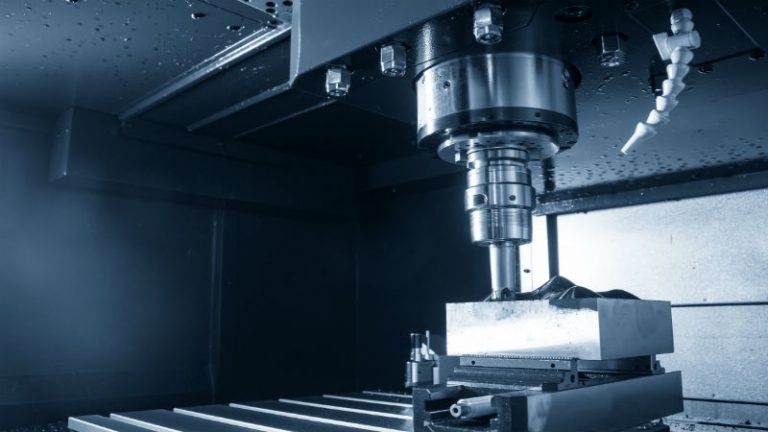

In the past, one-off projects were done manually, Examples of the equipment used in these tasks were the treadle guillotine, fly presses, pillar drills, and welding equipment. Today, a good deal of fabrication is done via laser cutting and computerized CNC machinery that automates most of the previously manual processes.

How Can I Learn More?

Besides performing internet searches, the best way to learn more is to visit a location near you. Contact the office and ask them for a tour and to see some samples of their work. That way, you can get a pretty good idea of what they can do for you. Then, back in your house, look around to see if there’s anything unique you want to add that can be done via steel fabricators.

Overall, metal fabrication continues to change. As we move into the world of the Internet of Things (IoT), how fabrication and technology meld will be even more important.