Imaging companies are considered to be the most scientific places out there and use the latest technology whenever possible. This technology isn’t cheap, so it makes sense that you have people trained on how to use the equipment. However, even with proper maintenance and care, you may find that the x-ray tubes inside your machine break or don’t work after a period of time. When that happens, you need a go-to option to design options to fit your needs and manufacture them for you.

How it Works

XRF technology is essential for most doctors and hospitals. The process begins by irradiating a liquid or solid sample with x-rays of high energy from a controlled source. If you choose portable or handheld instruments, you likely use x-ray tubes for the source, which offers many advantages over traditional radioisotopes. For one, there are fewer licensing issues. For another, the emissions can be modified to suit particular applications.

The primary components include the anode, cathode, envelope for the tub, housing, and a window. Each is described in more detail below:

- Cathode: This component expels electrons from circuits and focuses them into the beam and focal spot on the anode. The source is controlled to generate the beams. Electrons are created by heating your filament (tungsten wire coils). The heat forces the electrons from your cathode.

- Anode: This component produces the x-rays and includes a piece of metal shaped like a beveled disk that is connected to a positive. It converts electron energy into the x-rays and dissipates any heat.

- Envelope: This is an airtight enclosure that holds the anode and cathode.

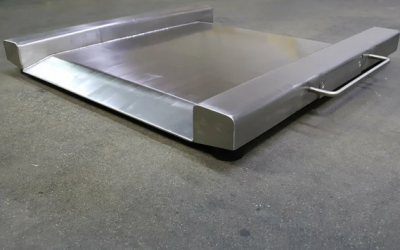

- Housing: This gives more protection and absorbs extra radiation.

- Window: The x-ray tubes have a window so that the rays can pass through while holding the vacuum so it can operate.

Learning about the scientific aspects of how things work is essential. Visit Micro X-Ray Inc. to have x-ray tubes designed for your needs. Visit them at https://microxray.com.